No business can survive without making a profit.

For many types of business estimating costs and calculating profit can be relatively straight forward, but in engineering, and especially in machining, it’s not. Not at all…..

Owning and running a machine shop is serious business.

It represents a huge investment in both time and money and takes years of study and experience to learn the trade, not to mention that the capital investment in machines and related equipment is considerable.

Put simply, the problem is knowing how to calculate your costs. Until you know exactly what a part or batch of parts will cost to manufacture it’s impossible to calculate a selling price and therefore your profit.

So why is this such a difficult problem for a machine shop?

In a nutshell, it’s difficult because of the huge number of inputs and variables that have to be taken into consideration. Not only are there a lot of them, but they are all quite dissimilar. For instance, you need to understand how to calculate exactly

what a new or existing machine tool really costs to own and operate.

What about finance charges? is it better to invest cash or to borrow? What about maintenance and downtime? Don’t forget labour costs. There is more to hiring staff than just paying an hourly rate. You need to cover things like health funds, pension contributions annual leave and sick pay etc.

Then there are the technical aspects of the job starting with the material. Do you have the most recent prices from your suppliers, and how much do you need? What about the machining itself? How long will it take to turn that shaft or mill that keyway or drill twenty-four M12 holes, 60mm deep with a 3mm chamfer?

What if there are aspects to the job that you cannot do yourself? You will need to use sub contractors. What do they cost? You may also need to invest in new equipment in order to fulfill the contract. To manually try and keep track of all these elements on a job-by-job basis is clearly a mammoth task. This is what QuoteCAM does effortlessly and accurately.

The least understood aspect of owning and operating a machine shop is the correct method for calculating the hourly rate to be charged for your machine tools and other work centres.

Work centres are anywhere that a batch of parts goes within your company to add value. Most often it’s a machine tool but not always. QuoteCam caters to all kinds of work centres including skilled and unskilled manual tasks, inspection and document checks.

QuoteCam takes into account every aspect of purchasing or owning a machine tool including lease payments, interest, depreciation, future value and maintenance costs.

It’s all done with one easy-to-use calculator that determines the exact cost of ownership and relates it to you at an hourly rate.

Many small and medium-sized businesses and it difficult to assess and properly monitor or control their overheads.

It takes a lot more than machine tools, materials and tradesperson to run an engineering business. Your company needs to pay electricity and water bills, rent or mortgage insurance, fuel, leave pay and public holidays. The list seems endless. Until now only the large manufacturers knew how to manage these costs.

With QuoteCAM even small machine shops can accurately calculate overhead and recover it in their cost analysis. QuoteCAM provides a powerful overhead burden calculator that will automatically reduce all your overhead costs into one simple hourly rate that can then be included in your quotes.

Having the right information at your fingertips is essential. QuoteCam already has a large selection of common materials that are arranged in groups, but of course you may add your own.

This means that adding a new material can be done in seconds by simply adding it to an existing group so that it inherits the correct speeds and feeds information.

QuoteCAM comes complete with a comprehensive supplier database that allows you to store all of your supplier’s contact information and sorts them by the goods they supply. Instantly contact your materials, tooling or sub-contract suppliers and include their goods or services into your quote.

Standard charges and minimum quantities are all catered for. At any stage of the quoting process, when you need to use any of your suppliers, QuoteCAM offers a unique ability called “E-Quote” With the click of a mouse QuoteCAM will email all the relevant suppliers requesting their latest pricing on the goods or services you require. QuoteCAM will then automatically update your database with the new pricing.

Take the guesswork out of estimating with our unique approach to estimating machining times. QuoteCAM offers a fast and easy-to-use, optional, machining calculator that automatically selects the chosen material and cutting data, as specified in your quote and then calculates machining times based on the operation and conditions you specify.

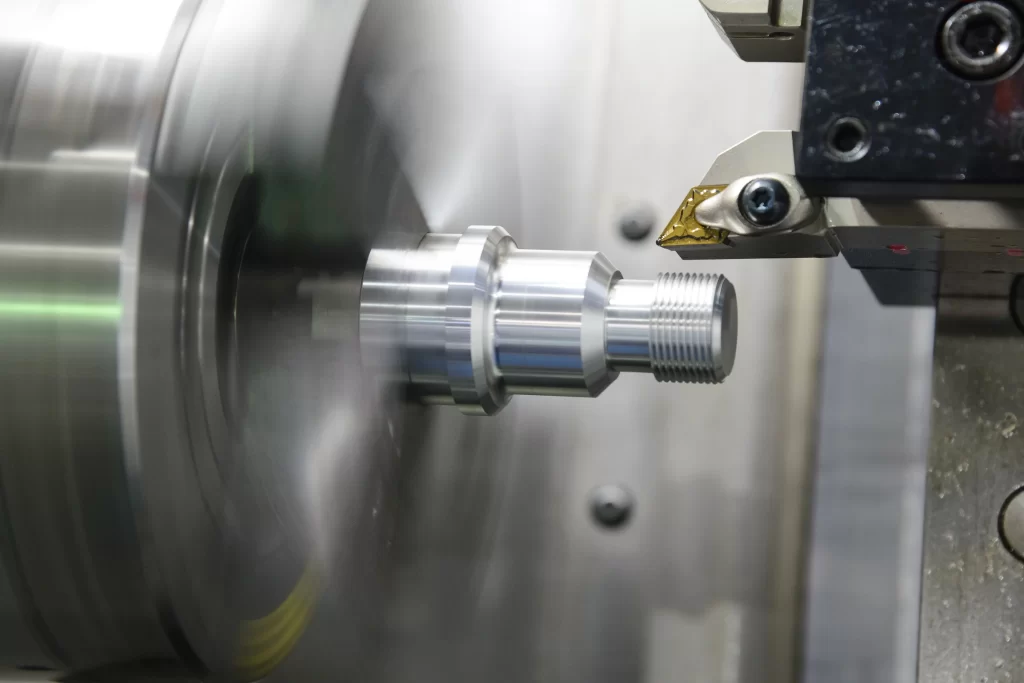

The turning estimator has been designed to simulate all of the common machining processes that are carried out on a lathe.

All of the basic information such as material, cutting feeds and speeds etc, are taken from the main quote so the user needs only to specify diameters and lengths of the journals and other dimensional information regarding the various features such as grooves, tapers and faces.

All the diameters on a shaft can be estimated in no time by simply entering diameters and lengths into a single form. The system immediately calculates the total time spent roughing and finishing and can even allow for tool change times.

All common milling operations such as pocketing, profiling, keyways and slots can be simulated and timed.

As with turning, times can be estimated for both carbide and high-speed steel tooling and cutters. A separate calculator is provided for face milling and blocking down operations.

All forms of hole production are covered including drilling, tapping and boring with counter-bores or spot faces.

QuoteCAM allows you to completely customise all of the processes and operations used in your business. The product ships with a wide selection of standard machining operations and you may also add, delete or edit as many as you need.

All types of manufacturing steps are considered including various forms of purchases.

Simple Purchase

This is for items that need to be bought, either for use during manufacturing such as a special sized drill or reamer or for items that form part of the finished product such as a bearing or key.

Sub-Contractor Purchase

Includes costs associated with a process that needs to be carried out by a third-party contractor, typically heat treatment, electro-plating etc. There are provisions for minimum costs and set up costs that may be applicable.

Consumables Purchase

This calculates the cost of purchasing disposable items that will be used in direct relation to the number of parts being produced. For example, you can allow a cost for a carbide insert that will last for a given number of parts. This form of purchase will be constantly updated with any changes to the batch quantity.

QuoteCAM is browser based which offers a true multi-user environment with a super fast and reliable database that allows simultaneous and concurrent use by your entire estimating team from anywhere in the world.

QuoteCAM works totally on a cost basis, that is to say, that every piece of information we use during the construction of a quote is entered as a cost value.

Only once you know exactly what the true cost of manufacture is can you determine your profit and selling price.

The sales price analyser is totally unique to QuoteCAM and is a powerful tool for evaluating your return on investment in time, materials, labour and overhead. Everything is presented in a simple to understand batch graph, that clearly shows the reducing cost curve for each part in the batch. Instantly see what the cost of manufacture is and what your return will be in percentages or dollars and cents.

Calculate your selling price based on either percentage margin or percentage mark-up. You can even choose to add margin to the raw materials separately from the rest of the process and add allowances for scrap items or inefficiencies.

Use the analyser to instantly recalculate your costs and selling price if a customer changes the batch size. If you need to match or beat a competitive quote the analyser can work backwards and instantly tell you what your margin will be in both percentages and money if you decide to meet or beat your competitor.

With QuoteCAM you have the correct information to help you make intelligent decisions.

If you need to reduce your costs and increase your efficiency the batch cost chart is the perfect place to start. It clearly outlines every aspect of your manufacturing costs on a batch-by-batch basis showing you exactly where small adjustments will have the maximum impact.

Download or Email your quotes via PDF that can be laid out using your own company letterhead and logo. Add your own notes and additional information as required.